Monitoil® is a patended product designed and developed by Mecoil Diagnosi Meccaniche srl

Advanced online oil monitoring system

On line system for oil conditions monitoring from remote.

Realtime analysis of multiple signals and data transfer to cloud based platform.

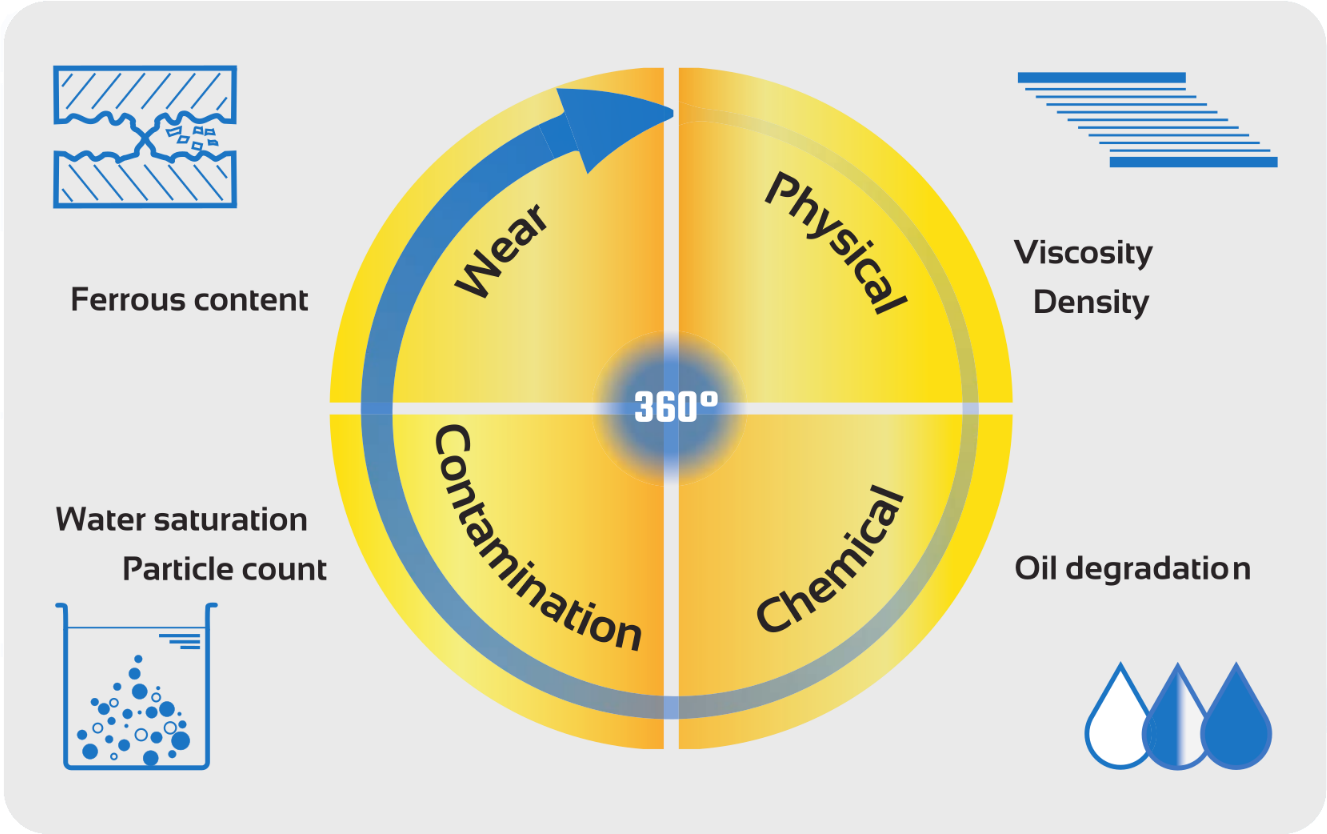

360° assessment of oil and machine conditions, enabling immediate actions.

What is Monitoil®?

Sensor suite

| Sensor | Description |

|---|---|

| Physical conditions | Suggested applications: Hydraulic systems, Turbines, Wind Turbines, Engine test facilities, Diesel Engines. This sensor measures the direct and dynamic relationship between multiple physical properties to determine condition and contamination of fluids.

|

| Particle counter ISOcode | Suggested applications: Hydraulic systems, Turbines, Wind Turbines, Engine test facilities. Not suitable for heavily sooted oils.

|

| Chemical conditions | Suggested applications: Hydraulic system, Turbines, Wind Turbines, Engine test facilities, Stationary Gas Engines.

|

| Ferrous Debris | Suggested applications: Gearboxes, Wind Turbines, Engine test facilities, StationaryEngines.

|

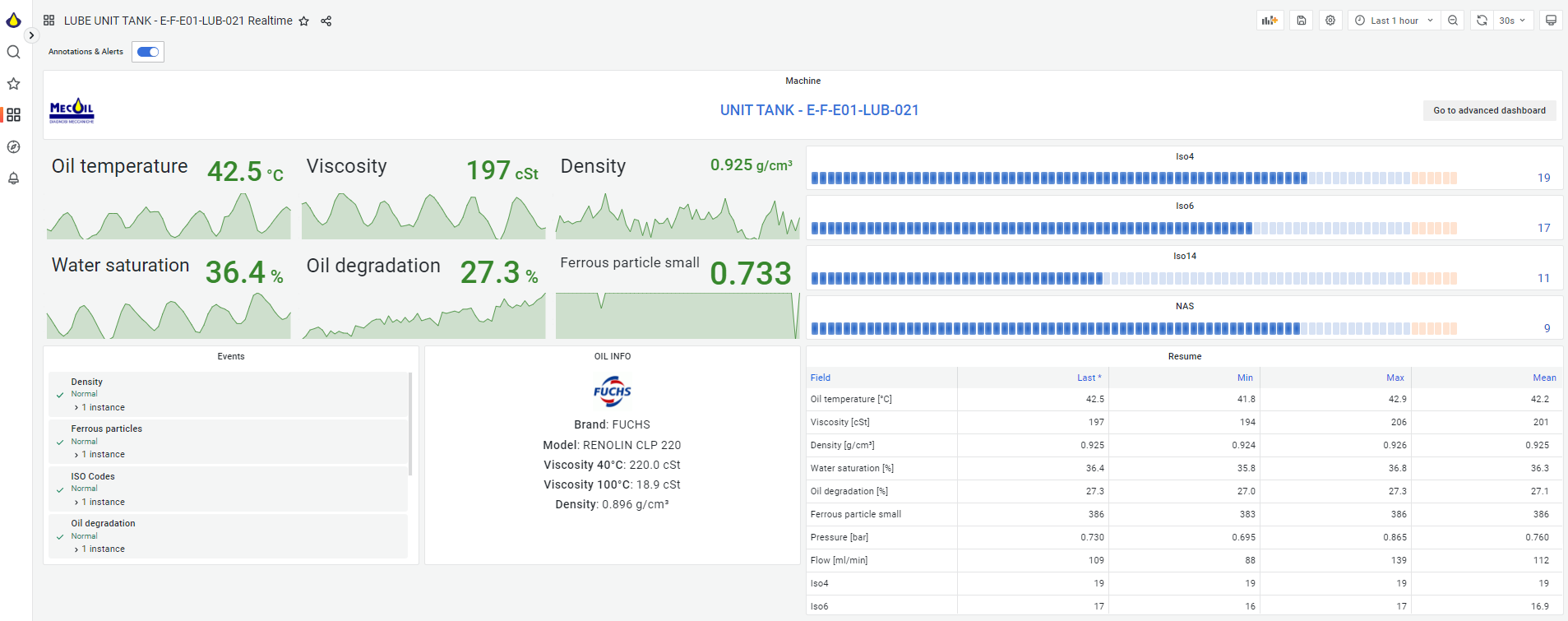

Monitoil® Manager

Realtime dashboard

Web cloud based software for real timedata collection and processing

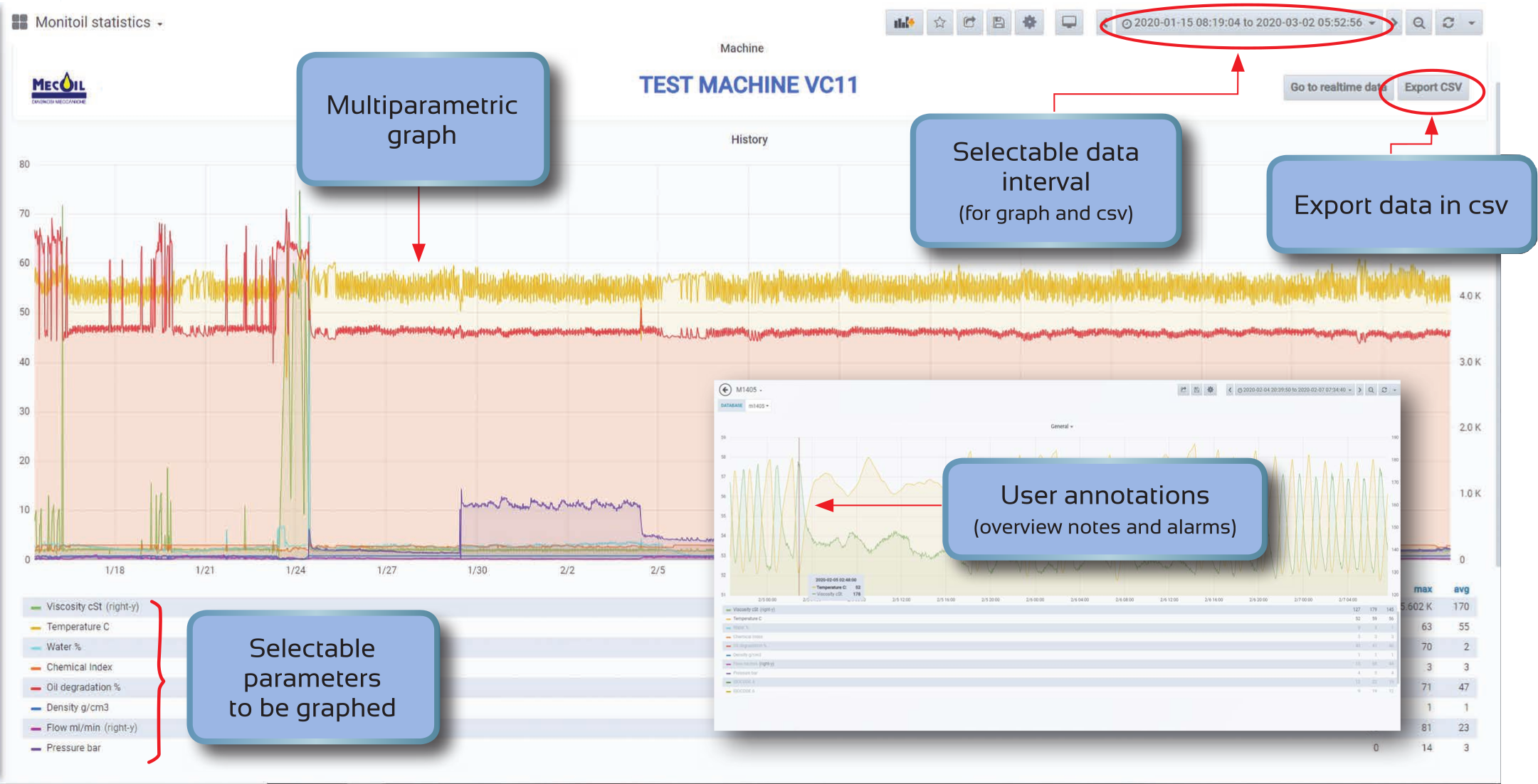

Advanced Dashboard

Different views allowed through selectable options

Benefits from Monitoil® use

- Monitoil® allows modern predictive maintenance based on real lubricant and equipment status.

- Continuously monitoring enables oil life optimation and drives cost-effective maintenance.

- Seamless wear trend evaluation allows timely corrective actions to prevent failures.

- Equipment integrity and personnel safety are guaranteed.

- Monitoil® detects wear onset, saving higly valuable asset integrity.

- Unexpected production losses are prevented and better managed.

- Oil samplig can be optimized in remote installations, reducing condition monitoring costs.

- Monitoil® 24/7 monitoring guarantees quick ROI due to manteinance costs optimization and failure prevention.

Tecnical specifications

| Power Supply | 24 VDC or 220 VAC |

| Analyzed fluid range temperature | -25°C* to 80°C (*compatible with the fluid pumpability) |

| Sensor Suitcase ambient temperature | -20°C to 60°C |

| Max oil pressure | 8 bar |

| Operating flow rate | 100 – 400 ml/min |

| Fluid viscosity | 1 to 400 cSt |

| Monitoil® electronics ambient temperature | -20°C to 60°C |

| Data transfer | 4G-LTE; Ethernet |

Contact us!

Would you like to understand if Monitoil® fits with your need?

Clicking below, you can describe your requirement.

You will be contacted soon.